Desiccant Air Dryers

- Home

- Desiccant Air Dryers

MPS Metro Automotive and The Fender Factory can do it all for you—your trusted one-stop shop for quality auto body supplies, expert service, and industry-leading automotive solutions.

Call Us When You Need Help!

Desiccant Dryers

Regenerative desiccant dryers adsorb moisture on solid desiccants, such as activated alumina, silica gel, or molecular sieves. Two desiccant-packed towers operate alternately; compressed air flows through the desiccant in one tower while the desiccant in the other tower is dried, or regenerated.Regenerative desiccant dryers supply the lowest dew point, usually -40°F but as low as -100°F. They are also the most expensive, so specify a regenerative desiccant dryer only when the application calls for maximum dew point performance. Regenerative dryers are often used to protect instrumentation and control systems, laboratory equipment, and moisture‐sensitive processes and materials. They also protect outdoor lines from freezing in severe weather conditions.

There are three different methods to regenerate the saturated desiccant bed: by a purge of dry air from the operating tower, by internal heaters, or by an external heat source. Here are the pluses and minuses of each:

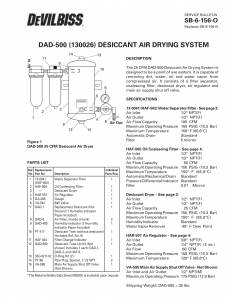

Heatless Dryers

Uses a purge of compressed air expanded to atmospheric pressure. It is a simple, safe process with low maintenance. However, the purge requires 15-18% of air capacity, resulting in high operating costs for larger systems.

Verdict: The least expensive choice for smaller systems with sufficient excess air capacity.

Heated Dryers

Uses electrical resistance or steam heat. Only about 4.5% purge air is needed. These units cost more initially due to complex controls and require skilled maintenance personnel.

Verdict: A balance of efficiency and cost, predominantly used in mid-range applications.

Blower-Purge

Uses an external blower to force heated atmospheric air through the tower, requiring no compressed air for regeneration. While they have the highest initial investment, they solve the issue of prohibitive purging costs in large installations.

Verdict: Used almost exclusively in large systems where energy efficiency is paramount.