Oil Free Compressed Air

The Purest Oil-Free Compressed Air

Oil-Free compressors do not remove the oils that are suspended in the ambient air, DV Systems’ ETC does it very well.

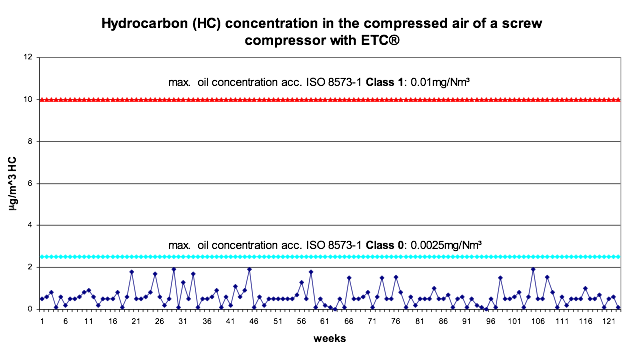

- Guaranteed oil-free compressed air according to ISO 8573 class 0.

- Achieving class 1 even with hydrocarbon concentrations of up to 154 000 parts per billion at the ETC inlet.

- Clean condensate with a hydrocarbon concentration downstream of the ETC <1.93 parts per billion and therefore allowed to drain without additional treatment or separation.

- Compared to many oil-free compressors, the condensate is not acidic but neutral with a ph between 6 and 7.

- Compared to oil-free compressors, independent of the ambient air quality.

- The ETC catalytic process also minimizes bacteria, fungus and microbial content in the compressed air.

- 20 000 workings hours or 30 months warranty on the catalytic function.

- The ETC is compatible with variable speed drive. compressors operating between 110% and 20% by using the VS module.

- Converts silicone monomers to silica and absorbs the silica.

- Compact design with improved insulation and reduced energy consumption.

- Electronic control unit and reduced number of electrical wear parts.

- Pressure drop over ETC system approx 5.8 psi at 100 psi.

- Absolutely secure system with a protective shutdown unit that prevents oil-containing compressed air from entering the network in the event of malfunction.

How It Works

The ETC CONVERTER by DV SYSTEMS

|

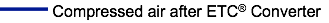

ISO Class “0” Oil-Free Air, ETC components

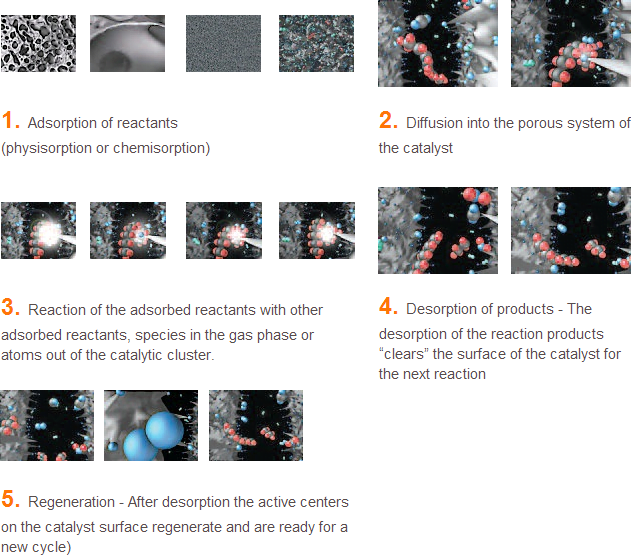

The ETC is integrated into the compressed air network downstream of the compressor. The compressed air (1) containing oil that is flowing from the compressor is conducted over a pre-separation unit (2) and a VS module (3) into a plate heat exchanger (4). The pre-separation unit protects the ETC against liquid oil and water. The VS module extends the maximum working range to between 20 to 110% of the nominal flow. The compressed air is pre-heated in the plate heat exchanger and then flows into the converter vessel (5) containing the catalyst (7). By using an electric heater (6), the catalyst is held at a temperature that is necessary for the catalytic to take place. The oil-free compressed air leaves the converter and is cooled down again in a counter flow in the plate heat exchanger and is conducted through an optional particle filtration unit (8) and the minimum pressure closing valve (9) to the outlet.

ISO Class “0” Oil-Free Air

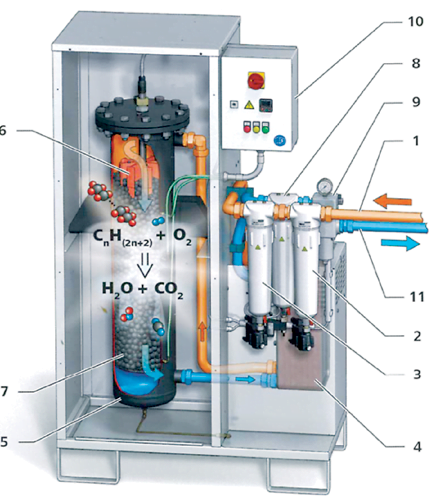

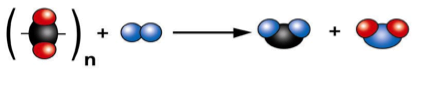

The DV Systems ECOTEC CONVERTER concept uses a special catalyst to convert the oil and other hydrocarbons into water and other harmless air components in a physical-chemical process (see above). All oil molecules are burnt completely and effectively in the EcoTec Converter. The compressed air is absolutely oil free and can be used without restrictions in all applications that require guaranteed oil-free compressed air. The process is not only very ecological but also most economical.

CATALYST PRINCIPLE

Chemical Reaction in the ETC

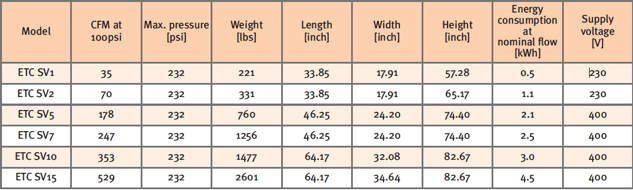

ETC Specifications

OPTIMIZED SYSTEM DESIGN

The quality of air required throughout a typical compressed air system can vary. The extensive range of purification equipment available from DV Systems allows the user to specify the quality of air for every application. DV Systems has a comprehensive range of purification equipment available to exactly match system requirements, ensuring both capital and operational costs are kept to a minimum.